The medical equipment industry is in a constant state of evolution, driven by technological advancements, increasing demands for precision, and a relentless pursuit of improved patient outcomes. This continuous upgrade cycle presents unique challenges, particularly in motion control systems where reliability, accuracy, and compact design are paramount. Right-angle gear motors are increasingly playing a crucial role in these upgrades, offering a versatile and efficient solution for a wide range of medical applications. This article explores effective right-angle gear motor configuration strategies for medical equipment, highlighting their benefits and addressing key considerations for successful implementation. We will also touch upon how current trends, such as remote patient monitoring and minimally invasive surgery, are influencing the demand for these components.

Traditional linear actuators and direct-drive motors are often unsuitable for many medical applications. Right-angle gear motors offer a valuable alternative, providing several key advantages:

The increasing sophistication of medical devices, fuelled by advancements in areas like artificial intelligence (AI) and Internet of Medical Things (IoMT), further reinforces the importance of right-angle gear motor technology. Data-driven insights from patient monitoring and remotely operated equipment necessitate robust and reliable motion control systems.

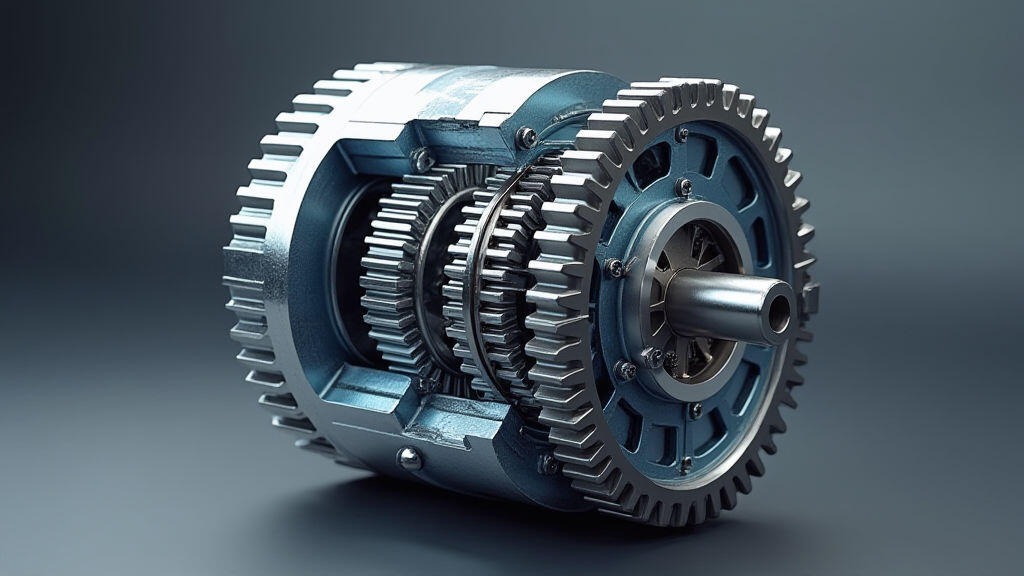

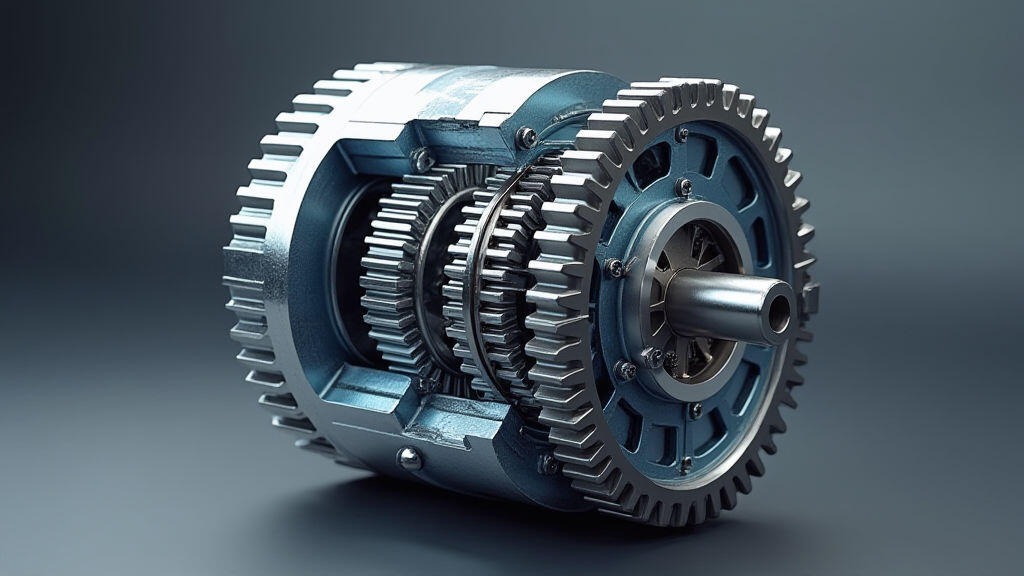

Choosing the right right-angle gear motor configuration is critical for optimal performance. Here are several strategies, tailored for diverse medical equipment applications:

1. Gear Ratio Selection: The gear ratio determines the relationship between motor speed and torque. Selecting the appropriate ratio is arguably the most important decision. For applications requiring high torque at low speed (e.g., robotic arm movements), a higher gear ratio is necessary. Conversely, applications needing high speed and lower torque (e.g., sample handling systems) call for a lower gear ratio. Manufacturers like MES-Drive offer a range of gear ratios to meet diverse requirements. Precise calculations and simulations are crucial to determine the optimum ratio.

2. Motor Type Considerations: The type of motor coupled with the right-angle gearbox significantly impacts performance.

3. Housing Material and Environmental Protection: Medical equipment operates in diverse and demanding environments. The gearbox housing should be constructed from materials like stainless steel or medical-grade plastics that are resistant to corrosion, chemicals, and sterilization processes. IP ratings (Ingress Protection) are essential to ensure protection against dust, water, and other contaminants. Applications near bodily fluids require specific sealing and biocompatible materials.

4. Lubrication Systems: Proper lubrication is critical for minimizing friction and wear within the gearbox. Options include oil lubrication, grease lubrication, and dry lubrication. The choice depends on the application's operating temperature, load requirements, and sterilization requirements. Self-lubricating gear designs are increasingly utilized to eliminate the need for external lubrication and simplify maintenance.

5. Encoder Integration: For applications requiring precise position feedback, integrating an encoder directly into the gearbox is crucial. Incremental and absolute encoders are available, offering varying levels of accuracy and resolution. High-resolution encoders enable fine-tuning and accurate control of the medical device's motion.

Several key trends are reshaping the medical equipment industry and impacting the demand for right-angle gear motors:

The market for right-angle gear motors in medical equipment is projected for continued growth, driven by the ongoing advancements in medical technology and the increasing demand for precision, reliability, and compact design. As technological complexities increase, MES-Drive is committed to developing innovative solutions that meet the evolving needs of the medical industry. Specifically, we are focusing on miniaturization, improved energy efficiency, and enhanced integration with AI and IoMT platforms. Further research into advanced materials and manufacturing techniques will pave the way for even more sophisticated and powerful right-angle gear motor configurations. The convergence of medical technology and advanced motion control systems positions right-angle gear motors as a cornerstone of future medical innovation.

Leave A Reply

Your email address will not be published. Required fiels are marked